www.automation-mag.com

12

'23

Written on Modified on

Stratasys News

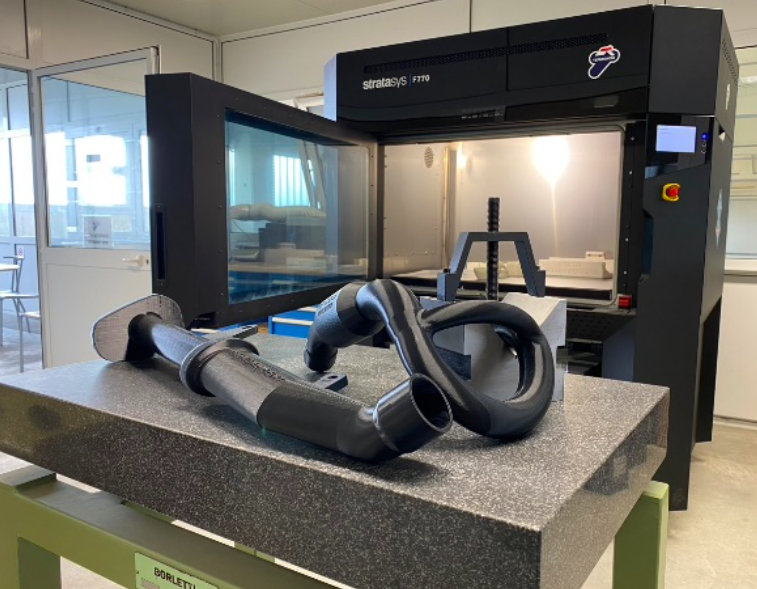

Termignoni achieved 50% cost savings and improved speed-to-market with Stratasys F770 3d printer

Termignoni has reduced production costs and time to market by using a new FDM® additive manufacturing solution from Stratasys.

The company shifted from outsourcing prototype part production to an in-house capability anchored by a Stratasys F770 3D printer. It has reduced costs by 50% and saved the company time waiting as parts were shipped across the country.

Termignoni supports motorcycle race competition across the world in different series, and also provides aftermarket systems for consumer-facing brands like Ducati, KTM, Yamaha, and Honda, pushing the boundaries of motorcycle exhausts in terms of performance, weight-reduction and acoustics.

Size matters

The large size of the Stratasys printer means fewer parts need to be glued together — reducing the risks of inaccuracies, errors, and inefficiency inherent to that methodology. Instead, the 1,000 x 610 x 610 mm build chamber allows the whole component to be 3D printed as a single piece. Termignoni achieved a cost saving of 50% based on the old outsourcing model through this production efficiency.

Termignoni is using ASA thermoplastic which, says Marinelli, provides more stability and a better surface appearance than certain other materials. The team is using ASA with soluble support materials that allow complex and internal structures to be designed and 3D printed with minimal post-processing requirements.

Adoption drives further innovation

The company has now created an ecosystem of capabilities anchored by the Stratasys 3D printer. “We have brought in a range of production equipment that we used to buy externally. By combining the F770 with metal laser cutters and CNC machines for example, parts such as jigs and fixtures for production and measurement processes can be completed internally,” says Marinelli.

www.stratasys.com