www.automation-mag.com

28

'23

Written on Modified on

DMG MORI News

DMG MORI TO PRESENT INNOVATIVE MANUFACTURING SOLUTIONS AT CIMT 2023

Modern machine tools for process integration, automation, digitization and sustainability will be the highlights at CIMT 2023.

For DMG MORI China International Machine Tool Show (CIMT), the country’s most prestigious machine tool exhibition is an ideal platform to present innovative solutions for the production of the future. From April 10 to 15, 2023, visitors will get an impression of DMG MORI’s technology excellence in the most important key industries. Process integration, automation, digitization and sustainability will be the major issues at DMG MORI’s booth.

Automation: Solutions for every purpose from a single source

Flexible automation of production processes is high on the agenda of an increasing number of companies. The better the utilization of a production facility, the better its economic as well as ecological balance. DMG MORI has been shaping this development towards increasingly autonomous processes for many years with innovative automation solutions. The portfolio now comprises 57 automation solutions in 13 product lines for workpiece or pallet handling – including the complete hardware and software. In addition, there are the PH‑AGV and WH-AMR driverless transport systems. DMG MORI can thus equip and in many cases retrofit 150 different machine models.

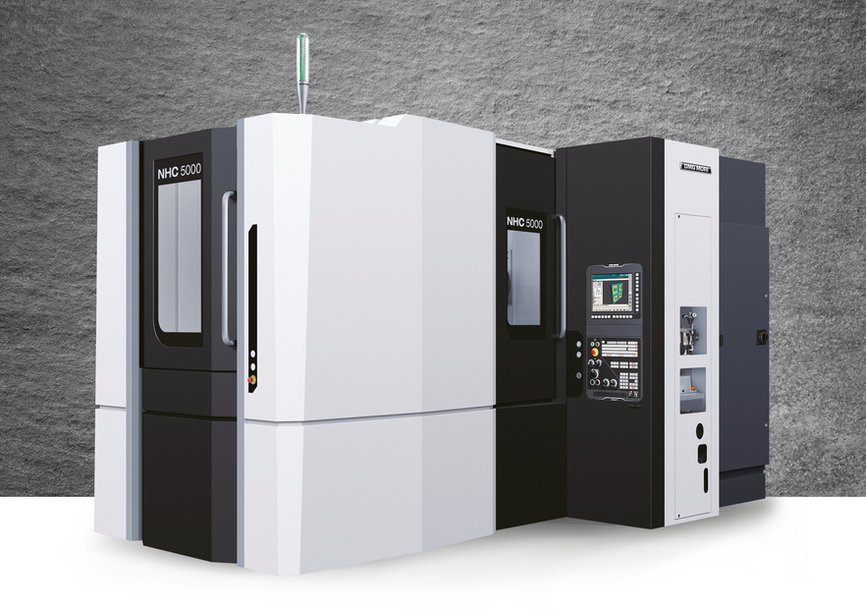

DMG MORI will be showing two examples of the automation portfolio at CIMT in the form of an NLX 2500 with a MATRIS light and a NHC 5000 with an RPS.

Integrated Digitization & Technology Integration - Innovative solutions for the digital transformation of a modern production

As a technology leader in machine tool manufacturing, DMG MORI can align all activities in the area of digitization along the entire value chain. CELOS and the Messenger support work on the shopfloor while the IoTconnector guarantees safe connectivity for the use of monitoring and remote services. Another example of digitization is the DMG MORI DIGITAL TWIN. By simulating whole machining processes in virtual space – from controls over tools and clamping devices to workpieces – the DIGITAL TWIN reduces the risk of collisions during the actual machining process. Component costs and cycle times can be reduced, as well, which makes machining significantly more productive.

Technology Excellence: Experts in aerospace, semiconductor, medical, die & mould and new energy

DMG MORI has decades of experience in many key industries. In recent years aerospace, semiconductor, medical, die & mould and new energy are becoming increasingly important. Thus, the machine tool manufacturer bundles this experience in its DMG MORI Technology Excellence Centers. With their technical know-how, their experts design individual manufacturing solutions with a continuous process chain based on the innovative product portfolio.

www.dmgmori.com