www.automation-mag.com

10

'19

Written on Modified on

EPLAN

Optimised information flows increase productivity Syngineer brings worlds together

Engineering disciplines must grow together in the Industry 4.0 era. But how can current departmental boundaries be overcome? Syngineer ensures that designers from electrical and mechanical engineer-ing “talk to one another”. The cloud-based tool facilitates better communication while simultaneous-ly optimising interdisciplinary cooperation for developing machines and systems.

For many design engineers, one of the central, day-to-day challenges is getting and providing information. Syngineer, an innovative cloud solution from Eplan and its affiliate Cideon, can help master this challenge. The software accelerates and simplifies coordination in engineering – specifically between mechanical engineer-ing, electrical engineering and PLC/software. The system ensures better collaboration by promoting cross-departmental information exchange. In doing so, it further reduces the number of manual tasks, that often occur at the last minute thus making them particularly costly.

Simple system for more transparency

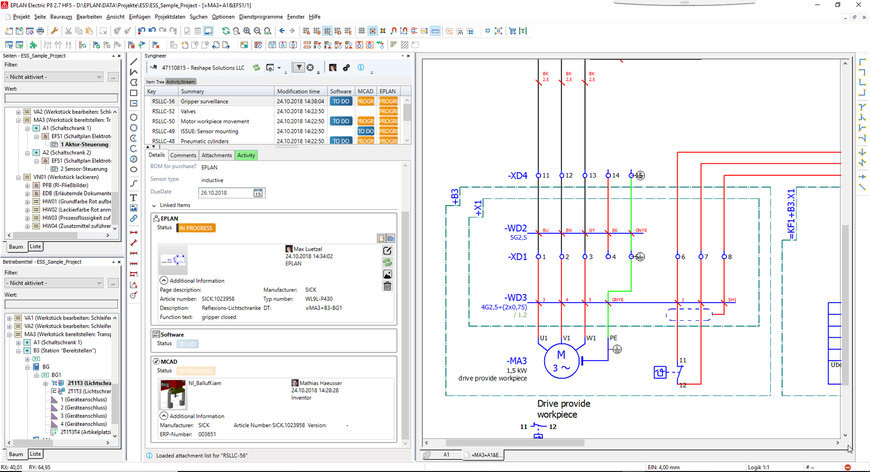

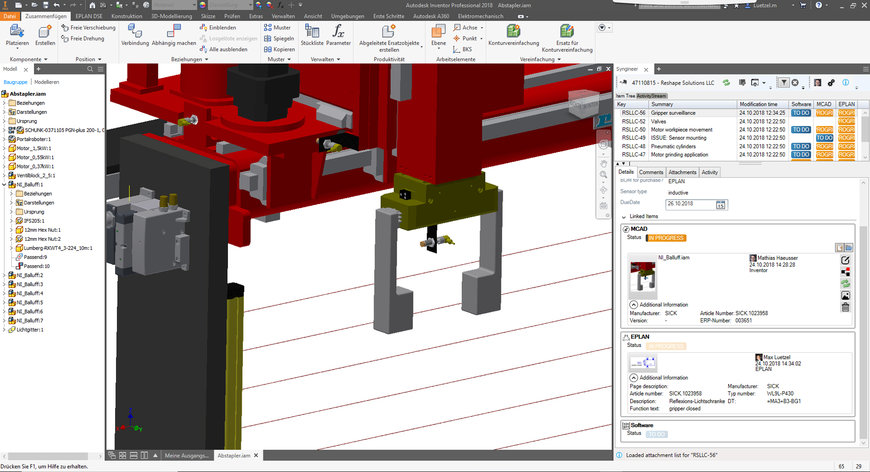

Syngineer takes a project-based approach for users. The application is simple: “Connectivity between the MCAD software and Eplan Electric P8 through Syngineer can be set up quickly and is easy to use,” says Max Lützel, Team Lead Consulting Syngineer. “After a short orienta-tion, colleagues are able to find out, for instance, if a motor in the design was changed later in the process.”

With Syngineer, electrical engineers initially get an additional navigator within their familiar working environ-ment. This navigator networks them across departments to their colleagues from mechanical engineering. The two design departments can exchange engineering infor-mation bidirectionally. With this integration, the mechani-cal and electrical design engineers continue to conven-iently work in their own systems and to coordinate the latest developments, for instance via the integrated chat function. Alternatively, they can also be informed of changes via e-mail. Settings are easy to customise via the notification management system.

Central overview of development status

Syngineer labels a task’s or request’s current processing status. Subsequent changes in the development process and their status are also visible to all relevant employees. The system further provides information about which employees have made which changes. Project managers thereby have a global overview of the project and can also outline post hoc customer requirements in a central location. The software is currently available in German and English - further software languages will follow. Access via internet browser, smartphone, tablet or notebook is naturally supported – a must in the era of globalisation.

Scalable system

Another significant practical advantage of the cloud technology foundation is that external partners, custom-ers and suppliers can also be easily integrated into the development process. An additional benefit of the cloud architecture is the flexible user scalability. Companies can vary the number of users at any time as needed and provide access to additional departments including production, commissioning and maintenance.

In Conclusion

Syngineer ensures efficient information exchange, saving both time and increasing product quality. The automatic creation of sensor/actuator lists with Syngineer offers even more savings potential, with companies reducing working times by 30 percent, not to mention the added benefit of increased documentation quality.

Syngineer_ECAD.jpg: Syngineer documents the project status – seen here using the example of electrical design. All the information can be exchanged bidirectionally between electrical engineering and mechanical engineering.

Syngineer_MCAD.jpg: Changes made in the mechanical engineer-ing CAD environment are now transparent and comprehensible for the electrical engineers.